From Spore to Store

A clean, sustainable protein powder may soon be on our grocery shelves, thanks to an exciting research project that combines the talents of a local entrepreneur and biologists at Acadia University.

Mycaro is the innovative creation of Katie McNeill, sparked by her experience of selling agricultural produce to large-scale grocery retailers.

“I came to the project through the lens of agri-food waste that we generate here in the Annapolis Valley,” McNeill says. “What can we do with it? What kind of value-added products can we make?”

“I discovered that certain types of agri-food waste lend themselves really well to growing high-protein mushrooms.”

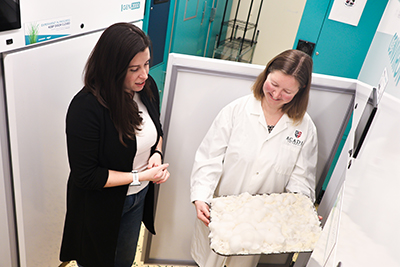

The research into the protein’s commercial viability is led by Dr. Allison Walker, a Professor in the Department of Biology and a mycologist. Dr. Walker and her team are growing high-protein mushroom roots, known as mycelium, on food waste generated during agricultural processing.

The Acadia process is yielding 40 per cent protein in the mycelium – very high by industry standards.

“We are making a zero-waste process, taking something that would otherwise be thrown away and adding value to it by increasing the protein content,” Dr. Walker says. “A big part of the initial research was trying to optimize the protein content and figure out the best way to do this process.”

McNeill was referred to Leigh Huestis of Acadia’s Office of Industry and Community Engagement after a successful pitch to Spark Nova Scotia had enabled her to work with a Prince Edward Island lab to produce initial data.

“I showed up at Acadia with an idea, some literature, and a little bit of data and explained what I wanted to do, and Leigh was quick to connect me with the right people,” McNeill says. “We were able to start working with Allison Walker right away once the funding was in place.”

“Through Acadia, we’ve achieved our proof of concept. We know that what we want to do will work technically, and we know we want to take this mycelium and process it into a protein powder.”

By early summer, McNeill hopes to be in the first phase of commercial production, ideally in a facility in the Annapolis Valley, where the food waste is generated. The aim is to have a food-grade product for pilot customers.

“Allison Walker has been extremely supportive,” McNeill says. “She and her colleagues have technical expertise but also the flexibility to work through an idea collaboratively. For an early stage company that doesn’t have deep pockets, an educational institution like Acadia is great to point you in the right direction, help you to make sure the grant applications are correct, and know how to execute the project through the grants.”

The research is taking place in the K.C. Irving Environmental Science Centre’s growth facilities for plants and fungi.

“The Mycaro Research Project through Dr. Allison Walker’s lab has been a wonderful addition to the research happening here,” says Sarah Hines, Research Manager & Irving Scholar Coordinator at the Centre.

“We are home to many multidisciplinary research projects, all connected to environmental sustainability. We are pleased to be able to offer state-of-the-art facilities and equipment to teams working on important topics to improve the quality of human life and the environment.”

McNeill will soon be looking for investors to help her company make this product on a larger scale and test it with consumers. When she finds a larger-capacity space, Acadia may help to train employees there and provide expertise at the start, Dr. Walker says.

“Acadia has a wonderfully supportive industry engagement office,” Dr. Walker says. “We’ve had lots of successful partnerships. All kinds of exciting things are happening, and we have state-of-the-art facilities and expertise. I really enjoy working with Katie McNeill to help her launch her idea.”

“Acadia has been essential to getting us to this point,” McNeill says. “Acadia’s expertise, research facilities, and openness to taking on new projects – and their industry outreach – made it possible to turn an idea into reality.”